WMS

Warehouse management system

Complete traceability | Barcode scanning | Operations automation | Warehouse space optimization

Efficiency & increased control in inventory management

What are the benefits that the WMS solution offers?

Reduced costs

By making the best use of the storage space, automating operations, managing products correctly, reducing returns and making the most of all the resources in the warehouse

Increased productivity

The new employees are trained in just a few days, and generally all the warehouse employees carry out the activities in a shorter time and with increased efficiency

Increased storage capacity

The placement of goods according to the suggestions offered by the system leads to the optimization of the available space and allows the company to store more goods

Warehouse visibility and resource control

You know all the time where each product is located, where the employees are, what activities they have carried out and what needs to be done in the next period.

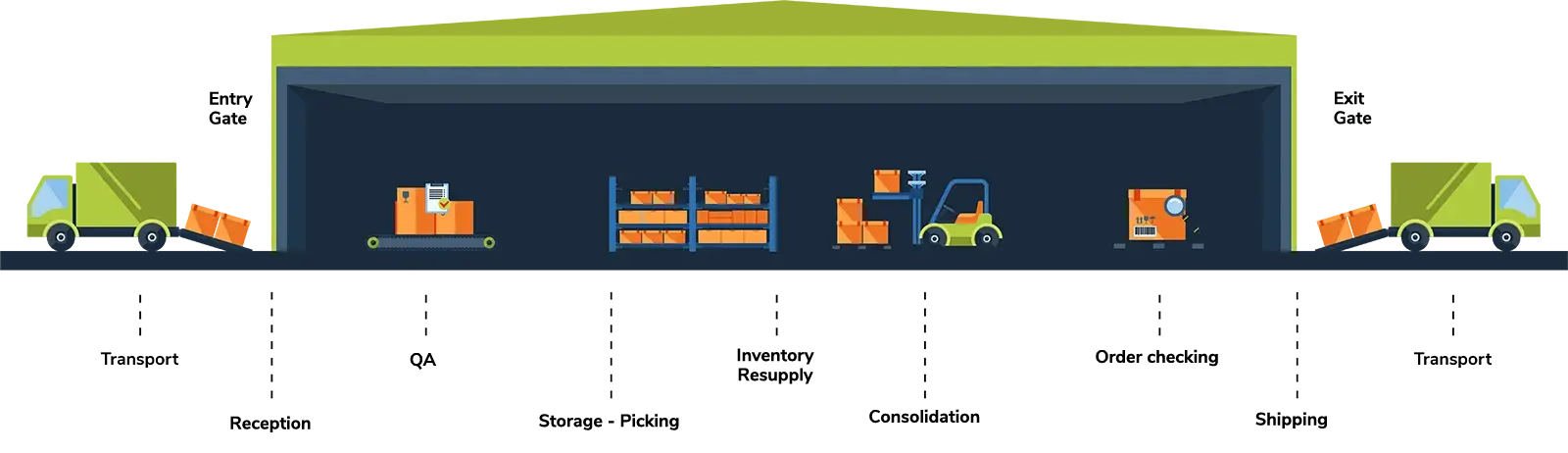

How is warehouse flow automation done?

Companies that implemented the WMS system obtained:

Traceability

Inventory accuracy

Accurate deliveries

Fewer returns

Increased efficiency, highprofitability , with the help of:

Delivery time improvements

By picking with the help of mobile terminals and organizing the activity in all stages of order preparation

Fewer returns

Orders are properly prepared, which leads to a significant decrease in returns that were caused by missing products or wrong quantities, for instance

Increased customer satisfaction

Fast and correct delivery of orders will make customers happy with the services offered and will persuade them to come back to you with new orders

Eliminate errors

With the help of mobile terminals, the warehouse employees can prepare the goods required by the customer in the desired quantity and with the correct specifications

Libris increased warehouse operations efficiency by 30%

“Overall, the implementation of WMS has streamlined the activity by about 30%. After implementation, the time was reduced on all operations: picking, goods reception, stock transfers.”

Find out more about the WMS system’s beneficiile !

Download factsheet!What other results do you get with the WMS solution?

Companies that chose WMS have seen visible results since the first months after the implementation of the system:

Fewer accidents

29Fewer material losses

82Reduced logistics costs

26Increased employee productivity

Increased stock rotation speed

Reduced inventory times

“We have full stock control and we can easily track important information automatically in one place. Moreover, the traceability of the products is ensured effectively on all flows performed after their reception in the warehouse, based on integrated reports. The system improves warehouse performance, product identification times etc.”

Cristian Stefanov – IT Manager Alexandrion Grup

THE WMS SYSTEM COVERS ALL WAREHOUSE OPERATIONS

Reception

The system automates and optimizes all operations associated with purchases, receptions or returns of goods, as well as cross-docking operations.

Inventory Management

Provides complete traceability through efficient and real-time management of all activities related to movement of goods and packaging within the warehouse.

Picking and deliveries

WMS successfully covers customer orders management and processing activities, stock allocation, picking, sorting, packing, consolidation and loading.

Warehouse control center

Through extended control functionalities, WMS allows you to track the activity of warehouse operators and freight movements, and you can achieve an efficient task management.

Extended Functionalities

Scenarios of inventory allocation or restocking, barcode and label management, kits management, unlimited intelligent logistical attributes, multilingual, multiwarehouse and multilocation.

Integrations

Easy import/export of data, integration with carriers (AWB automatic generation), integration with weighing systems and conveyors, integration with ERP and Ecommerce systems.

“We won in all the fields.. The most tangible benefit can be seen in the number of order lines processed in a day. With WMS we registered in a peak period 12,000 operated lines, compared to 7,500 before its implementation. The difference is big, especially on the stock control and visibility of the activities in the warehouse.”

George Samoila – Logistics Director, Royal Computers

Completely Automated Warehouse

Light-oriented systems

Automates the lifting and sorting operations:

Pick-to-Light

Pick-to-Cart

Put-to-Wall

Sort-to-Light

Pick-by-Voice

Pick-by-Voice

Voice-driven systems maximize the accuracy of picking operations and increase people's productivity due to the use of touch screens.

Automated storage and recovery systems

Automatic material handling systems such as:

Miniloads, Shuttles / Carousels

Pallet Stacker Cranes

Sorters, Cutting Machines

RFID Technology

Tehnologia RFID

For barcodes reading

For capturing and collecting information in inventory, entry and exit operations

Vison Picking

Vison Picking

By using smart glasses in combination with advanced voice recognition algorithms and RFID devices, Vision Picking technology enables hands-free warehouse operations.

Why should you choose the WMS solution?

Intuitive Interface

easy to use both from desktop and mobile terminals.

Configurable menus and windows

whose appearance and content can be changed as needed.

Workflows

which can be easily defined with the help of the system tools.

Easy access

at the mobile terminal screen by simply typing in some shortcuts.

Fewer typing errors

due to the existence of successive filters and validations.

Smart logistical attributes

whose existence allows to reduce customization needs.

What does offer it in addition to other solutions on the market?

Adaptability

The system easily adapts to the specifics of any type of business.

Workflows can be created according to the company needs and constantly improved.

Agility

Stock allocation on two levels: reservation & order preparation.

Multiple stock allocation scenarios for customer order fulfilment.

Intelligence

Included module for creating custom reports.

Integration with SeniorVisualBI solution for analysis and reporting.

Flexibility

Manage an unlimited number of attributes for items and packaging types.

Easy integration with any ERP system.

THE RIGHT SOLUTION FOR ANY INDUSTRY

3PL/4PL

- Manages multiple sales channels simultaneously

- Maximizes the use of staff and optimizes the storage space

- Flexible invoicing: eliminates hidden costs, highlighting hard-to-identify fees

- Cross-docking: reduces costs and space

- Return adaptability: the best performing reverse logistics management system

- Warehouse intelligence to increase efficiency and improve decision-making process

- Parcel management and partial truck transportation

Retail

- Manages multiple sales channels simultaneously

- Maximizes the use of staff and optimizes the storage space

- Promotions, packaging and labelling to support marketing and sales actions

- Optimized packaging according to needs

- Upstream and downstream traceability

- Parcel management and partial truck transportation

- Payment on delivery to stimulate sales and improve cash flow

- Processing orders from e-commerce

- Seasonality management: ensuring product availability for all seasonal waves

- ABC analysis: faster order preparation by placing at hand reach products with high rotational speed

- Intelligent logistical attributes — unlimited, related to items, stocks, orders, recipes

- Cross-docking operations for difficult products

- Combined delivery methods: direct (from supplier to store) and indirect (through retailer’s distribution center)

- Advanced stock allocation scenarios needed to support permanent promotions of different product versions

- Prioritization and different rules for suppliers

E-commerce

- Allocation of level 1 stocks by reservation of products ordered by customers

- Prioritizing orders through intelligent logistical attributes

- Various business scenarios: different picking methods depending on the type of products and the intended purpose

- Automation of order preparation processes: pick-to-cart; pick-to-light; pick-by-voice

- Integration of RFID technology for automation of warehouse activities

- Integration with materials handling automation systems

- Advanced order packaging and label printing systems

- Parcel management and partial truck transportation

- Efficient return management, along with return reasons and printing of return labels

- Integration with other ERP and WMS systems, interfacing with marketplaces, data import and export

Distribution

- Development and management of promotional packages to support marketing and sales actions

- Maximizes the use of staff and optimizes the storage space

- Advanced rules for unloading management: FIFO/FEFO

- Upstream and downstream traceability

- Repackaging and labelling, according to customer requirements

- High standards for frozen products

- Quality control of goods

- Integration with our solution for inventory planning and optimization

- Possibility to control the network of partners

- Automated stock allocation according to IKA delivery rules

Production

- A large number of items with different destinations can be traced: finished products, raw materials, semi-finished products, packaging

- Optimal use of storage space

- Optimization of material flow within the plant

- Automation and monitoring of quality control processes

- Batch tracking, consumption and production efficiency

- High accuracy of the product recall process

- Cross-docking to reduce costs and space

- Upstream and downstream traceability

- EDI integration to maximize visibility in relation to partners

Delaco has increased employee productivity by 25%

“The accuracy of the data was much higher and the number of errors was considerably reduced. In addition, the user-friendly interface of the WMS solution has reduced training times for new and existing employees.”

Marius Istrate, IT Manager Delaco

Internationally tested platform

SeniorWMS is developed on the Mantis platform, the leader supplier of logistics IT system and consultancy in Europe.

Implemented

by large companies on 3 continents

Used for over

24 years

by international companies

Present in over

20 countries

worldwide

Integrates good practices from

over 900

companies

“With the implementation of the WMS system, it is quite easy for our employees to prepare orders. They know from the very beginning which row, level or shelf to go to prepare the parcels. Thus, we manage to fully fulfil the orders for which we had stock in the warehouse and to have the highest stock accuracy.”

Marius Trifu – CEO Ocean Fish

Discover Senior Software's solutions:

ERP

Enterprise Resource Planning

BI

Data analysis with drag & drop

SFA

Sales agents & merchandising

TMS

Transport route optimization & shipment planning

E-COMMERCE

Online stores & B2B Platforms

APS

Advanced production planning & programming

MES

Manufacturing Execution System

HR

Human Resources Management

Clients

Romanian

Romanian English

English